All spun up

It’s been a while - such is life.

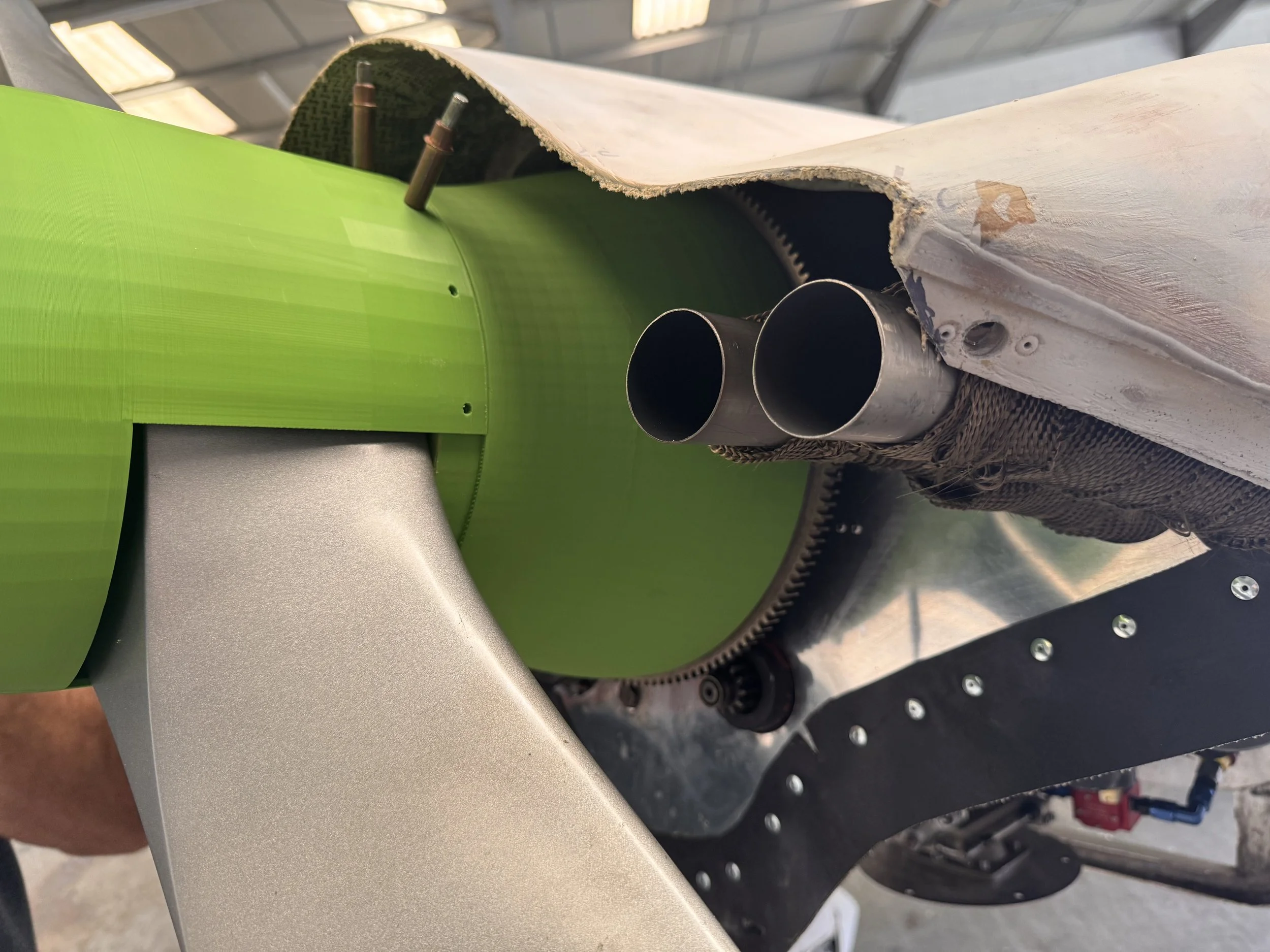

To make the spinner efficiently needed a huge upgrade in equipment, but with that in place we made final fit versions of the spinner and flow guide.

They’re smaller than before, providing slightly greater clearance for exhausting cooling air. This adjustment is needed given the move to in cowl exhausts. this dramatically reduced the clear airflow and may even result in some mods to use a Venturi tunnel round the exhausts to aid in drawing out cooling exhaust.

The pictures show the second to final fit, making sure clearances are reasonable or too loose. Now onto printing the moulds.

Spinner and flow guide are 2 main parts - as one might guess the spinner, and the flow guide.

Spinner - all carbon, will screw to the flow guide. the gap you see round the prop will be dramatically reduced and blended to the prop nicely. If made available for sale, there would be 2 additional pieces provided for the buyer to blend into their prop (or 3 for a 3 blade).

Flow guide - We are using an integrated crush plate, an earlier design had a separate crush plate that was Gould to be aluminium. We dropped thin in favour of a single piece flow guide crush plate. although it marginally increases complexity in the layup process, the ability to remove an entire machined aluminium part and reduce weight is a big upside.

The aim is to have this finished in the next few weeks - so it wont be ready for final inspection but maybe put on for first flight check.

Given the complexity and time involved in a the manufacture - its not cheap - aiming for a $1,300 price point. but $1,300 for an exposed carbon look is a small price to pay…